Register now!

Register now!

TAIWAN PLANTS FIBER TECH ALLIANCE CO., LTD.

2F-1., No.148, Sec. 6, Roosevelt Rd., Wenshan Dist., Taipei City 11674, Taiwan (R.O.C.)

About us

Taiwan First Alliance PFTA Co., Ltd. was established on June 28, 2017. With years of experience in the research and development process and application of plant fibers in the past, starting from the agricultural cycle, the high-quality application of the recycling of agricultural unused materials has developed natural, Non-toxic, zero petrochemical plastic environmental protection materials, and will develop the related materials to establish the PFP (Recycled plant fiber polymerized fully decomposed material) brand as natural plant fiber composite materials.

Global petrochemical plastic exclusion plan, PFTA's goal is to comprehensively promote agricultural waste fiber materials, recycle them for recycling and develop high-quality applications of various recycled fiber fully decomposed materials, and complete recycling systems to reduce carbon emissions, complete natural closed cycles, and apply recycling technology Improve the environment bit by bit to get back the earth's yesterday.

Please refer to the news coverage: https://www.taiwannews.com.tw/en/news/4038938

Our facebook page: https://www.facebook.com/Sugarcane-fiber-straw-100148425203963/?ref=page_internal

Instagram:https://www.instagram.com/twpfta/

Twitter:https://twitter.com/PFTA14

Website:https://www.pfta-bloc.com/

Products

Recycled Vegetable Fiber Cutlery Knife/Fork/Spoon

Sugarcane fiber straws have natural color and fragrance, which can allow users to take into account health and environmental protection, and reduce the harm of plasticizers to the human body and the pollution of plastics to the environment.

Sugarcane once played an important role in Taiwan's development history and was one of the important economic crops in Taiwan in the early days. Sugarcane fiber was selected as the research and development of sugarcane straw, because sugarcane itself is an edible crop, and the use of agricultural waste fiber as a straw material is very important. good application.

Ingredients: Natural regenerated sugarcane fiber, starch, pure biomass, etc.

MOQ: 100,000 pcs for a single specification

Product features: Product features: It has natural sucrose fragrance, does not contain traditional petrochemical-based plastics, plasticizers, non-toxic, no dyes, no fragrance, low manufacturing energy consumption, no waste water discharge, and low carbon footprint. There are natural fibers on the surface, and the fibers aggregate into particles, which is a natural phenomenon

Storage time: Unopened for about 12 to 24 months, store at room temperature, avoid high humidity and high temperature environment.

Precautions for use: The unopened product is recommended to be used for about 18 months. After 18 months, it may start to break down and become brittle, this is normal. If you find this to be the case, use it with care.

Decomposition method:

We can produce composting grades for industrial environments and environmental composting grades for home environments: 180 days in the corresponding environment, no toxic substances are released, trace carbon emissions, and no sucrose fragrance.

Relevant certifications:

1. The total dissolution rate of SGS food containers has passed the test, and does not contain any chemical additives. The chemical dyes are natural and non-toxic, and meet food-grade standards. SGS temperature is 50~85 degrees for inspection and certification.

2. PIDC plastic center excludes traditional 5P petrochemical pan plastic (PP, PS, PVC, PE, PET) certification

3. German DIN, American BPI, Japan and other raw materials can be compostable certification

4. Certificate of Origin of Sugarcane Fiber Raw Material, SGS No Pesticide Residue Certificate

5. Passing the 180-day decomposition standard of international general industrial environmental composting, the company's products reach full decomposition composting within 130 days, no toxic substances, no heavy metal report ASTM D6400/EN 13432

6. Obtained the Canadian CMA COMPOSTMANUFACTURING ALLIANCE, the food waste composting environment will be completely decomposed and fully composted within 2-4 weeks, up to 42 days.

Home & Natural & Marine Environment Composting Grades

PFTA.PFP recently developed and mass-produced straws with a higher level of decomposition environment

Home & Natural Environment Composting Decomposition Sugarcane Fiber Straws

Marine Environment Decomposition Grade Seashell Straw

more friendly to the environment

Production with lower energy consumption and carbon emissions

In addition to recycling agricultural waste fiber materials to manufacture PFP brand fiber composite fully decomposed materials

We continue to improve the research and development of raw materials and formulas

Decomposition grade formula and process of industrial environment compost

Directly upgrade to two different products of household & natural environment composting decomposition and marine environment decomposition

Provide more different options in the market

Minimum order quantity: 300,000 pcs for a single specification

In addition to raw materials, straws and various livelihood products, our PFTA.PFP can also provide more customized design services for customized product development and packaging development. Manufactured from different composting materials, to replace the pollution caused by petrochemical plastic products, and work hard for the global environment

Sugar Cane Fiber Straw Ø6/8/12 Bevel/Flat

With natural color and fragrance, sugarcane fiber straws can allow users to take into account health and environmental protection, reduce the harm of plasticizers to the human body and the pollution of plastics to the environment.

Sugarcane once occupied an important part in Taiwan's development history and was one of the important economic crops in Taiwan in the early days, and sugarcane fiber was selected as the research and development of sugarcane straws, because sugarcane itself is an edible crop, and agricultural waste fibers were used as straws Materials are an excellent application.

From the raw material processing and conversion technology, to the fiber particle formulation technology, to the final product production technology, all are the research and development efforts of our company team, and have obtained invention patents in the United States, China, Canada, Australia, the European Union (Germany, Britain, France) and other countries. .

Diameter Ø/D: 6/8/12mm (customized range of 3~12mm can be ordered)

Length L: 150mm/180mm/210mm / 240mm [Customized range of 100~450mm available]

Specifications: oblique cut/flat cut

Ingredients: natural recycled sugarcane fiber, starch, biomass pure material, etc.

Minimum order production quantity: 300,000 pcs for a single specification

Product features: Product features: It has natural sucrose fragrance, does not contain traditional petrochemical-based plastics, plasticizers, non-toxic, no dyes, flavors, low manufacturing energy consumption, no waste water discharge, low carbon footprint. There are natural fibers on the surface, and the fibers are aggregated into particles, which is a natural phenomenon

Recommendations for use: resistant to cold and heat -12 degrees to 50 to 85 degrees, it is recommended to drink cold and warm drinks, avoid hot drinks over 70 degrees, which will cause the danger of concentrated scalding!

Storage time: Unopened for about 12 to 24 months, store at room temperature to avoid high humidity and high temperature environment.

Note on use: The unopened straw is recommended to be used for about 18 months. After 18 months, the straw may decompose, which is a normal phenomenon. If you find this happens, please use it carefully and do not squeeze it hard.

Decomposition method:

Industrial environment composting decomposition level: 180 days in the corresponding environment, no toxic substances are released, trace carbon emissions, and sucrose fragrance.

Relevant certifications:

1. The total dissolution rate of SGS food containers has passed the test, does not contain any chemical additives, the chemical dyeing agent is natural and non-toxic, and meets food-grade standards, and the SGS temperature is 50 ~ 85 degrees inspection and certification

2. PIDC plastic center excludes traditional 5P petrochemical pan plastic (PP, PS, PVC, PE, PET) certification

3. German DIN, American BPI, Japan and other raw materials can be compostable certification

4. Certificate of origin of sugarcane fiber raw materials, SGS certificate of no pesticide residues

5. Passing the 180-day decomposition standard of international general industrial environment composting, the company's products reach full decomposition composting in 130 days, no toxic substances, no heavy metal report ASTM D6400 / EN 13432

6. Obtained the Canadian CMA Food Waste Composting Organization, and the food waste composting environment is fully decomposed and fully composted within 2 to 4 weeks and up to 42 days.

Recycled fiber cup lid

Sugarcane fiber straws have natural color and fragrance, which can allow users to take into account health and environmental protection, and reduce the harm of plasticizers to the human body and the pollution of plastics to the environment.

Sugarcane once played an important role in Taiwan's development history and was one of the important economic crops in Taiwan in the early days. Sugarcane fiber was selected as the research and development of sugarcane straw, because sugarcane itself is an edible crop, and the use of agricultural waste fiber as a straw material is very important. good application.

Ingredients: Natural regenerated sugarcane fiber, starch, pure biomass, etc.

MOQ: 100,000 pcs for a single specification

Product features: Product features: It has natural sucrose fragrance, does not contain traditional petrochemical-based plastics, plasticizers, non-toxic, no dyes, no fragrance, low manufacturing energy consumption, no waste water discharge, and low carbon footprint. There are natural fibers on the surface, and the fibers aggregate into particles, which is a natural phenomenon

Storage time: Unopened for about 12 to 24 months, store at room temperature, avoid high humidity and high temperature environment.

Precautions for use: The unopened product is recommended to be used for about 18 months. After 18 months, it may start to break down and become brittle, this is normal. If you find this to be the case, use it with care.

Decomposition method:

We can produce composting grades for industrial environments and environmental composting grades for home environments: 180 days in the corresponding environment, no toxic substances are released, trace carbon emissions, and no sucrose fragrance.

Relevant certifications:

1. The total dissolution rate of SGS food containers has passed the test, and does not contain any chemical additives. The chemical dyes are natural and non-toxic, and meet food-grade standards. SGS temperature is 50~85 degrees for inspection and certification.

2. PIDC plastic center excludes traditional 5P petrochemical pan plastic (PP, PS, PVC, PE, PET) certification

3. German DIN, American BPI, Japan and other raw materials can be compostable certification

4. Certificate of Origin of Sugarcane Fiber Raw Material, SGS No Pesticide Residue Certificate

5. Passing the 180-day decomposition standard of international general industrial environmental composting, the company's products reach full decomposition composting within 130 days, no toxic substances, no heavy metal report ASTM D6400/EN 13432

6. Obtained the Canadian CMA COMPOSTMANUFACTURING ALLIANCE, the food waste composting environment will be completely decomposed and fully composted within 2-4 weeks, up to 42 days.

Recycled Vegetable Fiber Cutlery Knife/Fork/Spoon

Sugarcane fiber straws have natural color and fragrance, which can allow users to take into account health and environmental protection, and reduce the harm of plasticizers to the human body and the pollution of plastics to the environment.

Sugarcane once played an important role in Taiwan's development history and was one of the important economic crops in Taiwan in the early days. Sugarcane fiber was selected as the research and development of sugarcane straw, because sugarcane itself is an edible crop, and the use of agricultural waste fiber as a straw material is very important. good application.

Ingredients: Natural regenerated sugarcane fiber, starch, pure biomass, etc.

MOQ: 100,000 pcs for a single specification

Product features: Product features: It has natural sucrose fragrance, does not contain traditional petrochemical-based plastics, plasticizers, non-toxic, no dyes, no fragrance, low manufacturing energy consumption, no waste water discharge, and low carbon footprint. There are natural fibers on the surface, and the fibers aggregate into particles, which is a natural phenomenon

Storage time: Unopened for about 12 to 24 months, store at room temperature, avoid high humidity and high temperature environment.

Precautions for use: The unopened product is recommended to be used for about 18 months. After 18 months, it may start to break down and become brittle, this is normal. If you find this to be the case, use it with care.

Decomposition method:

We can produce composting grades for industrial environments and environmental composting grades for home environments: 180 days in the corresponding environment, no toxic substances are released, trace carbon emissions, and no sucrose fragrance.

Relevant certifications:

1. The total dissolution rate of SGS food containers has passed the test, and does not contain any chemical additives. The chemical dyes are natural and non-toxic, and meet food-grade standards. SGS temperature is 50~85 degrees for inspection and certification.

2. PIDC plastic center excludes traditional 5P petrochemical pan plastic (PP, PS, PVC, PE, PET) certification

3. German DIN, American BPI, Japan and other raw materials can be compostable certification

4. Certificate of Origin of Sugarcane Fiber Raw Material, SGS No Pesticide Residue Certificate

5. Passing the 180-day decomposition standard of international general industrial environmental composting, the company's products reach full decomposition composting within 130 days, no toxic substances, no heavy metal report ASTM D6400/EN 13432

6. Obtained the Canadian CMA COMPOSTMANUFACTURING ALLIANCE, the food waste composting environment will be completely decomposed and fully composted within 2-4 weeks, up to 42 days.

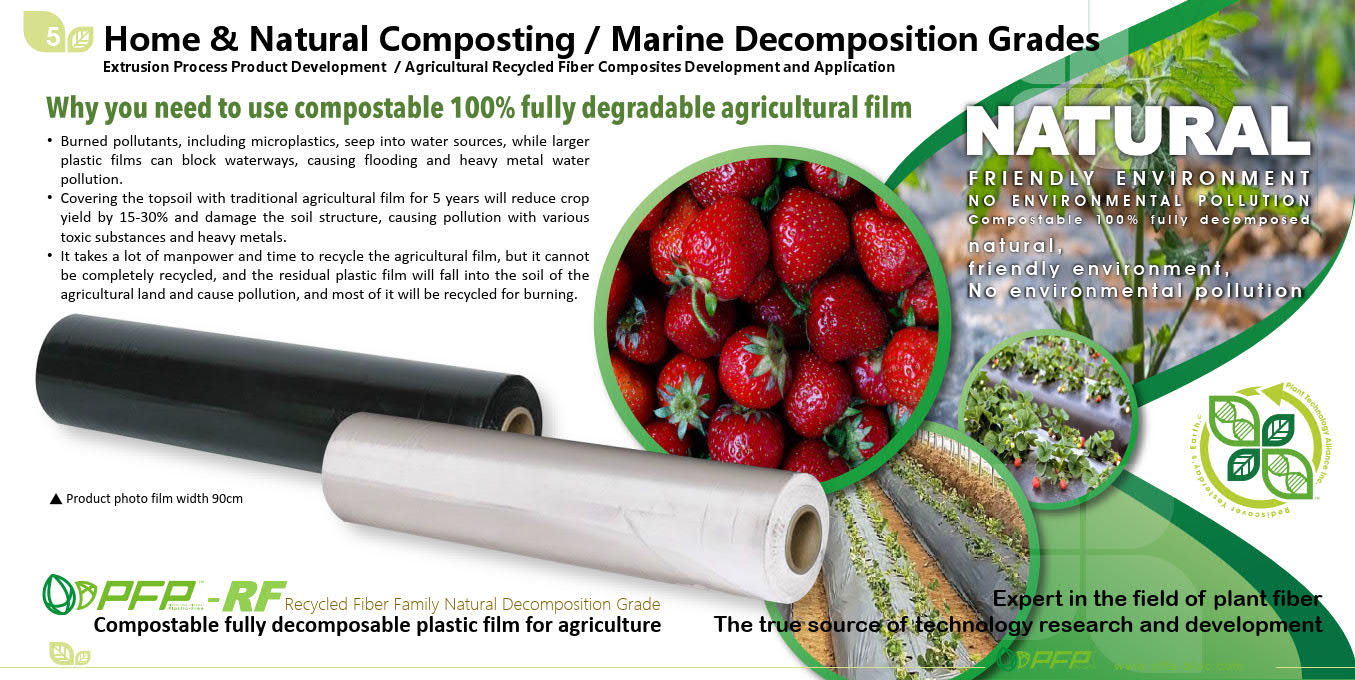

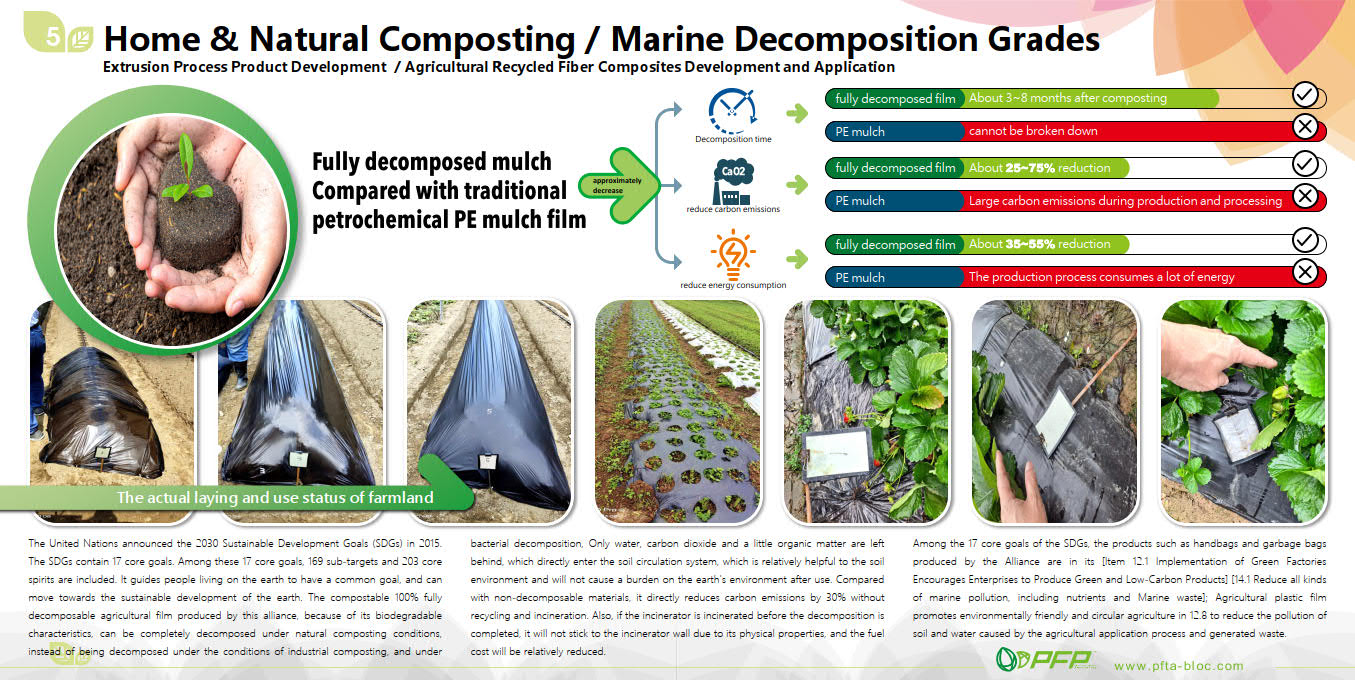

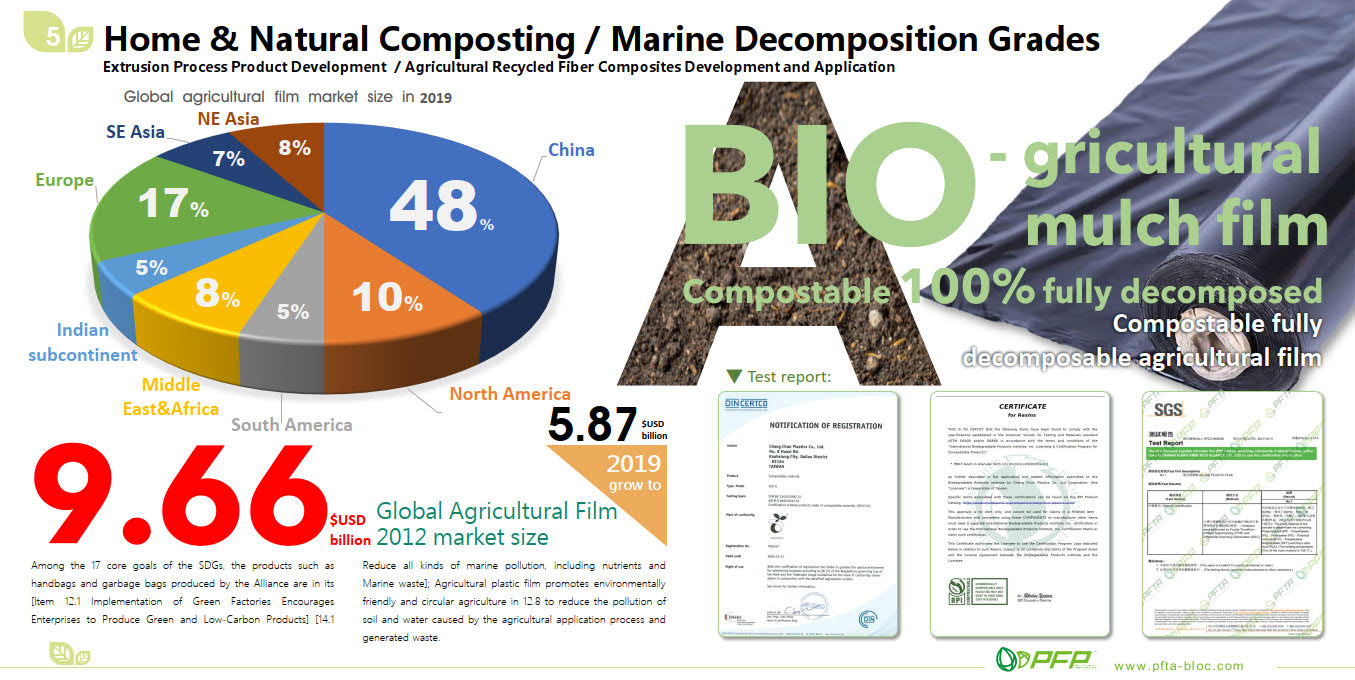

Fully decomposed mulch film for agriculture

Our PFTA.PFP recycles various waste fibers that are not used in agriculture to create a more friendly recycled fiber composite fully decomposed agricultural film, which will replace the serious damage to the agricultural planting environment and soil and plastic pollution caused by traditional petrochemical PE agricultural film. Fully decomposed agricultural mulch film, providing non-toxic and natural recycling friendly products for agriculture, so that the crop planting process can be at ease, more friendly to the soil, no pollution at all, and reduce carbon emissions

Minimum order quantity: 100 pieces of a single specification